Surface Well Testing Equipment

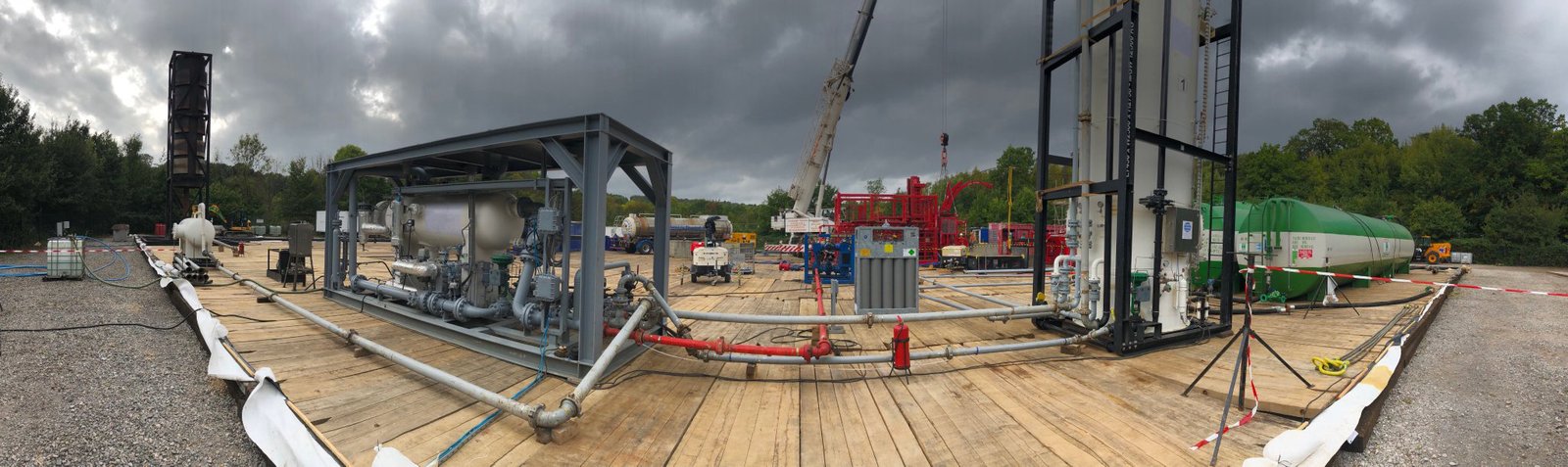

GOSCO provides a series of surface testing and metering equipment suitable for specific environment, which can effectively deal with the formation fluids produced by the completion device.

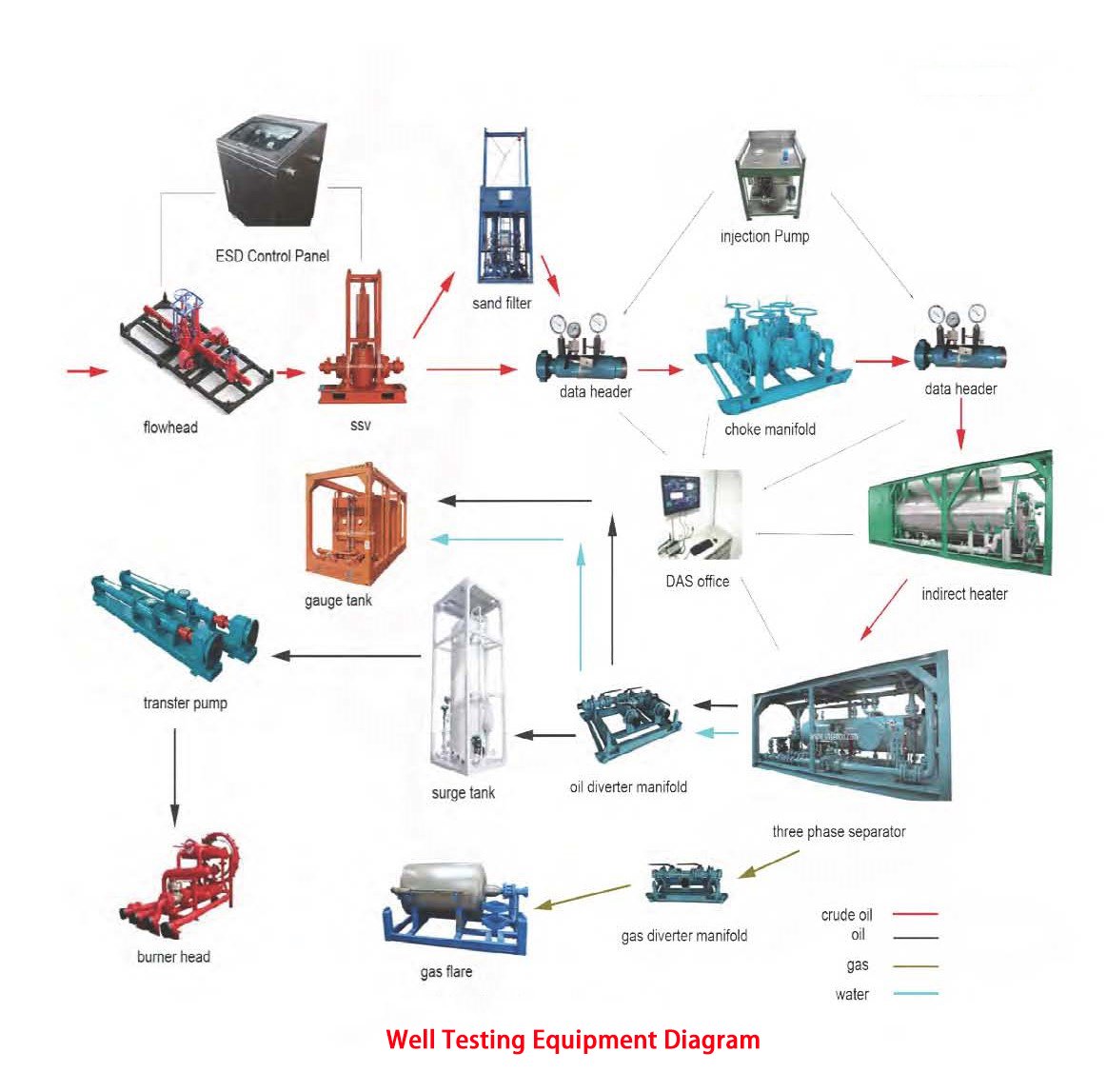

Surface well testing equipment or surface well testing package consists of items, such surface test tree, surface Safety Valve (SSV), data header, choke manifold, steam heat exchanger, test separator, vertical surge tank, oil transfer pumps, oil diverter manifold and burner.The main purpose of the well test equipment is acquisition of the reservoir’s data. Well test equipment is only way the collect data of the reservoir’s oi, gas, water, and condensate. Well test equipment shall be safe in operation meeting HSE requirements, effective and accurate to get data of productive capacity of a reservoir, and condition and characteristics of reservoir to adequate analyze reservoir performance and to forecast future production under various mode of operation. Data from surface well testing shall be accurate and reliable, so the client may make critical decisions regarding further test, oil and gas production and other programs in drilling and oilfield operation.

Our well testing equipment is designed and manufactured in accordance with international standards. All materials meet the quality standards of the United States, Europe, Korea, and Russia, such as CE / PED, ASME, API, GOST and other standards.

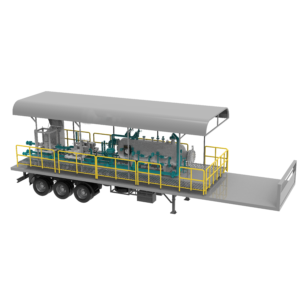

Trailer-mounted well testing equipment

Trailer-mounted well testing equipment can be fit in special-purpose trailers, which enable clients to conduct fast and effective well testing and fast mobilization of the equipment. Also, known as Dual Trailer system which equipped with manifold, separator, surge tank in one trailer, and data collection and control point on second trailer. Trailer structure and number depends the client’s requirements or can be proposed by our company.

Trailer-mounted well testing equipment is a portable system for separating and measuring well fluids, consisting of processing components like separators, manifolds, and surge tanks, along with utility equipment such as generators and a lab cabin, all mounted on one or more trailers for easy deployment. These systems are used to gather vital reservoir information for production evaluation and management, with customizable designs available to meet specific operational needs and pressure/flow rate requirements.

Core components

-Test separator: A crucial piece of equipment that divides well fluids into two, three, or four phases (oil, gas, and water).

-Choke manifold: A system of valves used to control the flow rate and pressure from the well.

-Surge tank: A horizontal tank for collecting and holding the separated fluids.

-Data headers: Include upstream and downstream data heads for measuring flow and other parameters.

-Meters: Equipment like Coriolis mass flow meters are used for accurate liquid and gas measurement.

-Pumps: Crude oil transfer pumps are used to move fluids.

Supporting and utility equipment

-Lab and office cabin: Provides a space for personnel to operate the equipment and perform analysis.

-Power generator: Supplies power to the entire system.

-Air compressor: Provides air for pneumatic controls and other functions.

-Heat exchanger: Used to heat fluids if necessary.

-H2S equipment: Includes necessary pipework for handling hydrogen sulfide.

-Safety equipment: Emergency shutdown (ESD) systems and surface safety valves (SSV) are included for safety.

-Flare trailer: A trailer for safely flaring excess gas.

Key features and benefits

-Portability: The trailer-mounted design allows for easy and quick mobilization to different well sites.

-Customization: Systems can be designed and built according to customer specifications and operational requirements.

-Efficiency: Provides a self-contained, fully autonomous system for well testing.

-Reduced footprint: Compared to skid-mounted systems, trailer-mounted equipment can be more easily transported and deployed, particularly in difficult-to-access areas.

Composition of Surface Well Testing Package

- ESD System

- Data Header

- Choke Manifold

- Test separator

- Surface Test Tree

- Oil transfer pumps

- Vertical surge tank

- Steam heat exchangers

- Oil diverter manifolds

- Atmospheric gauge tank

- Other auxiliary equipment

- Instruments and laboratory

- Surface Safety Valve (SSV)

- Control and Automation systems

- Burner

Surface safety valve

Surface Safety Valve (SSV) is one of the imp ortant safety equipment of the well testing operations with high flow rate and high pressure. Controlled by ESD system, SSV automatically shuts down the flow and prevent injury of personnel and damage of the facility.

3-1/16” 10000psi

Actuator: Hydraulically

Closing System: Fail Safe

API 6A, PR1, PSL3, DD

ESD Control Panel

Emergency Shutdown (ESD) Console is a particularly important component of surface well test system, as ESD console supplies hydraulic force to emergency shutdown valves to close flow line instantly if emergency like high pressure or high temperature occurs during well testing and production.

ESD console or ESD control panel consists of several components like air-driven hydraulic pump, pilot valves, check valve, strainer, SS liquid tank with indicator, pressure indicators, needle valves, regulators flow control valves, push button, regulator, ball valves, cylinders, and other auxiliary components. As a construction material for control panel and station stainless steel usually is used. For convenient transportation and operation, HC can design special skids with lifting lungs made from carbon steel.

Discharge pressure – 6000 psi

Power Source: Instrument Air (120 PSI)

Reservoir Capacity: 36 L

Other Features:

– H/L Pressure control

– Fusible plug control loop

Hydraulic pneumatic pump

Max allow. shutdown period 10 seconds

Data Header

Data Headeris high pressure assembly for collection of data wellbore production parameters, such as pressure, temperature, sand condition. Also, Data Headers used for chemical injection and safety purposes. Data Header usually installed before and after Choke Manifold.

Our Data Header provides essential access to the flow stream for pressure and temperature data acquisition, fluid sampling, and chemical injection. With versatile port configurations, customizable valve options, and compliance with industry standards, HC’s Data Header ensures reliability, flexibility, and precision in every operation.

3”, 10000 psi

Working Temp: -20 to 212 degF

6 ports for for sensors, chemical injection,

and sampling and thermo well.

API 6A, PR1

3”, 5000 psi

Working Temp: -20 to 212 degF

6 ports for for sensors, chemical injection,

and sampling and thermo well.

API 6A, PR1

Choke Manifold

Choke Manifold is an assembly which consist of high-pressure valves and chokes, used for reducing the pressure from the well head. It is operated by opening and closing an adjustable or fixed choke.

The Choke and Kill Manifolds are among the necessary pieces of equipment needed in oil and gas production.In the oil and gas industry, the Choke and Kill Manifolds are used in controlling well kick and pressure fluctuations.

The Choke Manifolds produced by our company have strong corrosion resistance, and the use of Choking manifolds can control wellhead pressure and improve safety. It can prevent formation sand from entering the well by limiting the flow rate, and can also prevents water and gas coning by limiting the flow rate. It maintains a certain flow rate, as required for testing. A test can require different flow rates over several time periods, requiring the use of different choke sizes.

HC designs and manufactures Choke Manifold assemblies with sizes ranging from 2 inches to 4 inches and pressures up to 15,000 PSI, suitable for both standard and acidic conditions. In addition to standard choke and wellhead manifold designs, we also offer customized manifold solutions.

Our Choke Manifolds are available in 5,000; 10,000; and 15,000 psi, all bore sizes,Welcome to consult! We ensure competitive prices and fast delivery.

3 – 1/16, 10000 psi , 5 Gate Valves

Working Temp: -20 to 250 degF

1 – Adjustable Choke Valve

1 – Positive Choke Valve

Sets of choke beans: From 4/64” to 64/64” in 4/64” increments and from 72/64” to 128/64” in 8/64” increments.

API 6A, PR1

Spare parts: Extra one set of choke beans

Three-phase separator

Three-phase separator is a basic component of petroleum production system, which is used to separate reservoir fluid from oil, gas and water. Then these separated flows are transported to the downstream for processing.

In general, a mixed fluid can be considered as a small amount of liquid A or/and gas B dispersed in a large amount of fluid C. In this case, the dispersed liquid A or gas B is called the dispersed phase, while the large continuous fluid C is called the continuous phase. For gas-liquid separation, it is sometimes necessary to remove tiny droplets of liquid A and C from large amount of gas B, where gas B is the continuous phase, and liquid A and C are the dispersed phases. When only one liquid and gas is considered for separation, it is called a two-phase separator or a liquid-gas separator.

The basic principle of separator is gravity separation. By making use of the density difference of different phase states, the droplet can settle or float freely under the combined force of gravity, buoyancy, fluid resistance and intermolecular forces. It has good applicability for both laminar and turbulent flows.

Our three-phase separator adopts advanced technologies of effective separation,throttling,automatic control,comprehensive anti corrosion and skid-mounted structure,and has the characteristics of high separating effeciency,high automation,stability,high measurement precision and accurate data details.

48”*10’, Standard Service

Corrosion Allowance: 3 mm

Design pressure: 1440 psi

Design temperature: 32 to 212 F

ASME Section VIII Div 1, U Stamp, ASME B 31.3

Material as per NACE MR 0175

Gas Meter-Orifice 1 x 6 in. 600 LB -China brand

Chart Recorder – Peterson/Equal,

Water Meter-Turbine 1 x 2 in. 600 LB – China brand

Oil Meter-Turbine 1 x 3 in. 600 LB – China brand

Pressure Control Valve 1 x 3 in. 600LB – Kimray/ Equal

Level Control Valve 1 x 2 in. 600LB – Kimray/ Equal

Level Control Valve 1 x 3 in. 600LB – Kimray/ Equal

Sets of manual ball valves – China brand

Sets of Relief Valves & instruments (level, pressure, temperature) — China brand

Steam Heat Exchanger

Steam heat exchanger is a special item of surface well testing, which is designed to safely and effectively heat the well stream. Steam heat exchanger can be equipped with choke valve to reduce flow pressure before media enter downstream 3-phase separator. Steam for steam heat exchanger is supplied by a boiler which is usually installed in safe area, providing additional

Surface Test Tree 3-1/16″

Pressure Rating: 10000psi

Temperature Class: P-U

Material Class: DD

Body material: AISI4130

Bonnet material: AISI4130

Gate/seat material: AISI4130

Kill Connection: 3″ Fig. 1502 F

Flow Connection: 3″ Fig.1502M

SERVICE: Oil & Gas, H2S Service

Design Code: API 6A ANSI B31.3 NACE MR-0175

Crude Oil Transfer Pump-Atmospheric Pressure

Transfer pumps used for filling and emptying the tanks and increasing the pressure for burner boom. Pumping unit is equipped with explosion proof electrical motor and control panel. The common type of pump is centrifugal, while gear and screw types are also available depending on the operation conditions.

Flow Rate: 30m3/hr

Head of pump: 30m

Withstand pressure: 3MPa

Connection pipe: DN80xSch40

Explosion-proof Electric motor

Pump * 2nos.

Surge Tank

Vertical surge tank is the part of the well test system, designed to perform the function of secondary separation after test separator, as well as the storage of the produced liquids and gases from the test separator. Surge tank can be classified as single-compartment and twin compartment based on the requirements of well testing operator. In well testing, surge vessel usually consists of pressure vessel (usually sour service), sight glasses (level indicators), pressure and temperature indicators, relief valves, level alarm system, and skid. Some clients might require pressure control valves as the part of the skid vale and piping. In some areas with high presence of waxy substances, the vessel of the surge tank is designed with steam-heated heating coils to ensure proper temperature for further oil transferring. Frames (skid) of the surge tank is required to be designed as per DNV standard and shall be approved by this agency in some operation areas.

Surge tank is filled by the fluids coming from the test separator and further delivered to the gauge tank or directly to the flare for further disposal. Unlike the gas of test separator, gas of surge vessel usually disposed through the vent pipe, which is installed far from the operation personnel to avoid casualties.

In some offshore platforms, the surge tank replaces the atmospheric gauge tank, and shall comply with DNV requirement based on local requirements to the certification. Pressure vessel is designed as per ASME standard with ANSI flange connection.

Single Compartment,

Working Pressure: 150 psi,

Working Temp: 20 to 121 degF,

Vessel Capacity: 50 bbl,

Material of Shell & Head: SA516 Gr.70

Control Valve

Relief Valve

Sets of manual ball valves

Level Gauge

Pressure & Temperature Gauge

All valves & instruments are Chinese Brand

Steam Heat Exchanger

Steam heat exchanger is an unit of well testing package, which plays an important role to ensure well fluid reaches the necessary temperature level before entering the test separator.

As steam heater transfers the heat from the steam to the well fluid, it can be considered as special type of heat exchangers, mostly used during well testing and well clean-ups. Configuration of the steam heat exchanger depends on the requirements of the oilfield service company or an operator, usually consists of flow-control valves, choke valve, level indicator, pressure and temperature gauges, safety valves and steam pressure controllers.

As steam heater transfers the heat from the steam to the well fluid, it can be considered as special type of heat exchangers, mostly used during well testing and well clean-ups. Configuration of the steam heat exchanger depends on the requirements of the oilfield service company or an operator, usually consists of flow-control valves, choke valve, level indicator, pressure and temperature gauges, safety valves and steam pressure controllers.

4.33 mmbtu , 1440 psi Coil Size 4”

Effluent Inlet & outlet: 4”

Steam Inlet outlet: 2” fig 206

Choke valve, control valve

Sets of valves and instruments

skid-mounted, ASME VIII, ANSI B31.3

Oil Diverter Manifold

Diverter manifoldis valve assembly, used for diverting the produced oil and gas to the proper process destination. Oil diverter manifold diverts oil to the burner boom or surge tank, while gas diverter manifold diverts to flare stack or burner boom.

Constructed with high-quality materials and engineered to withstand the demanding conditions of oilfield environments, the Oil Diverter Manifold features a robust structure comprising pipelines, valves, connectors, and flow meters. These components work together seamlessly to regulate the flow of oil, allowing for precise control and distribution.

Compliance with industry standards and rigorous quality assurance procedures ensure that the Oil Diverter Manifold meets the highest performance and safety requirements. It is designed to enhance productivity, minimize downtime, and facilitate efficient oilfield management.

Size: 3″, 5 ball valves

Working Pressure: 1440 psi,

Working Temp: -20 to 212 degF,

H2S Service

Gauge Tank

Atmospheric Gauge Tank is the vessel designed for temporal storing of the crude oil after the separation in the separator and surge tanks, used in onshore and offshore well testing operations. Being the part of the well testing system, Atmospheric Gauge Vessel mainly used to measure the flow rate and calibrate liquid metering instruments of the test separator. Atmospheric Gauge Tank has inlet and outlet of the crude oil. Oil enters from the surge tank and emptied by the oil transfer pumps.

Atmospheric gauge tank consists of the enforced vessel to ensure proper storage, sight glasses (level gauges) to control oil level, flame arrestors on each vent of the vessel, a grounding strap, and shearing roof to prevent the vessel from overpressure. Nowadays, gauge tanks rarely used in offshore well test operations and replaced by the surge tank. Also, gauge tank is not used in areas where H2S is presented as this is hazardous to the operation personnel.

Our atmospheric gauge tanks are designed and manufactured for various volumes and pressures.

Capacity: 200 bbl (2x100bbl)

Service: Standard

Double compartment

Pressure: atmospheric

Temperature: 32 to 212°F

Inlet / Outlet Connections: 3”Fig.602 Union

Drain: 1” Fig.602 Union

Skid-mounted

Construction material: Carbon Steel as per ASME

Code & Standards: ANSI B31.3

Includes level gauge

Pressure gauge

Temperature gauge

Breath valve

Sample ports

Sets of manual valves

Hammer unions

Chinese Brand

Laboratory and Office Cabin

The laboratory and office containers are the special designed and fabricated containers used both in offshore and onshore to provide necessary utilities and operating space for the personnel. Design and Fabrication standards of utility container vary from country to country and can be equipped with various devices to meet the client’s operation needs.

The cabin is used as modular laboratory often with several testers, instruments and meters, such as thickness tester, hydrometers, tubes, refractometer, digital and mechanical manometers, thermometers, measuring devices for CO2, H2S, pH, Salinity and other devices. Size of the container depends on the client’s requirements, but usually have similar height and width to fit the transportation requirements, while length can vary depending on the client’s requirements.

Dimensions: 10 ft. x 8 ft. x 8.6 ft.

Including the following equipment:

Entry/Exit Door

Escape Hatch, Window

Office desk and chairs

Plugs and other electric connection

Gas Detector, Air Extinguisher

Air Conditioner with Indoor and Outdoor units

Interior Refurbishments, Office tools; UPS

Sets of oil & gas laboratory equipment

Skid mounted, with lifting lugs and for forklift lifting

High Pressure Flowlines Package

Connection Piping Straight

3” Fig.1502

Working Pressure: 10000psi

Connection between Well Head and Choke Manifold

Length: 10m

Connection Piping Straight

3” Fig.1502

Working Pressure: 10000psi

Connection between Choke Manifold, Heater, Vessel, Gauge Tank and Pump

Length: 100m

Flare System (Simplified) (Preliminary model-LD-DN150-2000)

Burner boom is assembly used for the disposal of the produced fluids during the operation. Burner assembly has combustion water injection system for proper burning and operation.

Maximum Processing Capacity: 700,000 Nm³/day.-Manual ignition

Flame Arrester: DN150, PN2.5.

Windshield: ∮410×5 Stainless Steel.

Maximum Remote Ignition Distance: 300 meters

Electric Ignition Device: DC 12V, 2A.

The control box is at least 50 meters away from the electric ignition device.

Flare Stack Height: 3 meters.

Trailer

Trailer length 40-45 ft

Payload: 40 tonnes

Trailer width 8 ft

Trailer Height 4.8 m

Ex-proof LED lights

Ladder & handrail

Note: GOSCO Energy can design and fabricate trailer-mounted equipment based on the client’s requirements, while serial models from own development is also available.

1. GOSCO Energy can design and fabricate trailer-mounted equipment based on the client’s requirements, while serial models from own development is also available.

2. Please note that GOSCO Energy can equip trailer mounted surface well test equipment with domestic brand valve and instruments, as well as world famous brand valve and instruments depending on your requirements. Please be specific about part brand names or ask HC for personal suggestion based on your requirements to the brand and performance.

GOSCO Energy is a manufacturer and supplier of trailer-mounted packages in China. Please feel free to contact GOSCO Energy for more technical information and price. We ensure that trailer-mounted equipment will be in compliance with international standards and meet your requirements to the quality and expectation to the price.