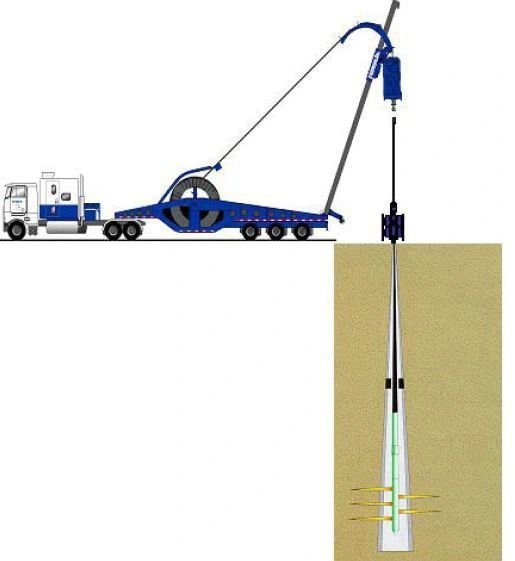

Perforation is a process used in oil and gas wells to create holes in the well casing, allowing hydrocarbons (oil or gas) to flow from the reservoir into the wellbore. This is typically done using perforation guns loaded with explosives.

Why Use Coiled Tubing (CT) for Perforation?

Perforation guns are usually deployed on a wireline, which works well in vertical wells. However, wireline has limitations:

1. Cannot push in deviated or horizontal wells – Wireline relies on gravity, so it struggles in wells that are not straight.

2. Limited load capacity – Wireline cannot support very long or heavy perforation gun strings.

To overcome these issues, Coiled Tubing (CT) can be used to convey perforation guns to the required depth.

Advantages of Using CT for Perforation

Can reach deviated and horizontal wells since CT can be pushed and does not rely on gravity.

Can carry heavier and longer gun strings due to its higher load capacity.

Can provide depth accuracy if an electric cable inside the CT is used with a gamma ray/casing collar locator (GR/CCL) tool.

This method is part of rigless operations, meaning it does not require a full drilling rig, making it cost-effective and efficient.