What is a Progressive Cavity Pump (PCP)?

A Progressive Cavity Pump is a positive displacement pump consisting of a single helical rotor that rotates within a double-helical elastomeric stator. As the rotor turns, cavities form and move along the stator, progressively pushing fluid from the inlet to the outlet in a smooth, continuous motion.

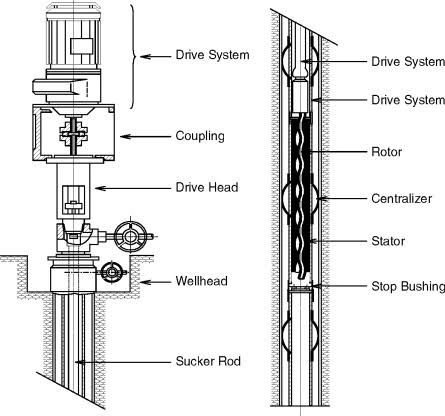

Components of a PCP System

1. Rotor: A metallic, helical-shaped shaft that rotates inside the stator.

2. Stator: A rubber-lined, double-helical housing that provides a sealing surface for fluid movement.

3. Drive System: Can be surface-driven using a rod-string or submersible motor-driven in downhole applications.

4. Production Tubing: Carries the produced fluid to the surface.

5. Surface Drive Head: Transfers rotational energy from the motor to the rod-string.

How PCP Works

As the rotor rotates inside the stator, it creates sealing cavities that trap and transport fluid.

The continuous movement of these cavities ensures a steady, pulsation-free flow.

The system operates efficiently at low speeds, reducing wear and energy consumption.

Advantages of PCP in Oil Production

1. Handles Viscous Fluids: Well-suited for heavy oil and emulsions.

2. Tolerates Solids and Sand: Effective in wells with high sand and solid production.

3. Energy Efficient: Lower power consumption compared to other lift methods.

4. Smooth Flow Delivery: Reduces shear stress on produced fluids.

5. Simple and Cost-Effective: Lower maintenance costs compared to ESP (Electric Submersible Pumps).

6. Operates in Deviated and Horizontal Wells: Flexible design allows for installation in complex well trajectories.

Limitations of PCP

Elastomer Degradation: High temperatures, chemicals, or gas intrusion can damage the stator.

Limited High-Pressure Capability: Not suitable for very deep wells with extreme pressure conditions.

Requires Specialized Maintenance: Proper selection of stator materials is crucial for longevity.

Applications of PCP in Oil and Gas

Heavy Oil Production: Ideal for producing high-viscosity crude oil.

Sand-Prone Wells: Can handle wells with high sand content without rapid wear.

Coalbed Methane (CBM) Wells: Used in dewatering applications.

Dewatering Gas Wells: Efficient in reducing water content in gas-producing wells.