Types of Drilling Operations

1.Exploration Drilling

Conducted to identify and evaluate potential hydrocarbon reservoirs.

Typically involves drilling wildcat wells in unexplored areas.

2.Development Drilling

Drilled in known reservoirs to maximize hydrocarbon recovery.

Focuses on optimizing well placement for efficient production.

3.Appraisal Drilling

Aims to assess the extent and quality of a discovered reservoir.

Helps in estimating reserves and planning field development.

4.Production Drilling

Wells are drilled to extract oil or gas commercially.

Includes vertical, horizontal, and multilateral wells for enhanced recovery.

5.Directional and Horizontal Drilling

Used to reach targets that are not directly below the drilling rig.

Improves reservoir contact and maximizes production rates.

6.Offshore Drilling

Conducted in deepwater and ultra-deepwater locations.

Requires specialized rigs such as jack-up rigs, semi-submersibles, and drillships.

7.Geothermal and Injection Drilling

Wells drilled for geothermal energy production or fluid injection for enhanced oil recovery (EOR) and waste disposal.

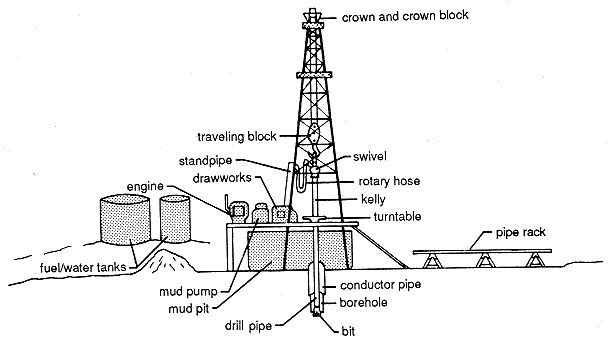

Key Components of a Drilling Rig

1.Derrick/Mast: The towering structure that supports the drill string.

2.Rotary System: Includes the drill bit, drill pipe, and rotary table/top drive for rotating the bit.

3.Circulation System: Uses drilling mud to cool the bit, remove cuttings, and maintain wellbore stability.

4.Blowout Preventer (BOP): A critical safety system that prevents uncontrolled fluid flow and blowouts.

5.Power System: Diesel generators or electrical motors supply energy to the rig.

Drilling Methods

1.Rotary Drilling

The most common method, using a rotating drill bit to cut through rock formations.

Requires drilling mud for cooling, lubrication, and pressure control.

2.Percussion Drilling

An older method that involves hammering the rock using a heavy drill bit.

Less efficient for deep wells but useful in hard rock conditions.

3.Directional Drilling

Uses downhole motors and steering tools to drill at angles or horizontally.

Essential for reaching reservoirs beneath obstacles such as cities, lakes, or environmentally sensitive areas.

4.Coiled Tubing Drilling

Utilizes flexible coiled tubing instead of traditional drill pipe.

Enables continuous drilling without making pipe connections, reducing downtime.

Drilling Fluid (Mud) and Its Importance

Drilling fluid, commonly known as drilling mud, serves multiple functions:

Cooling and lubricating the drill bit

Carrying rock cuttings to the surface

Maintaining wellbore stability

Controlling formation pressure