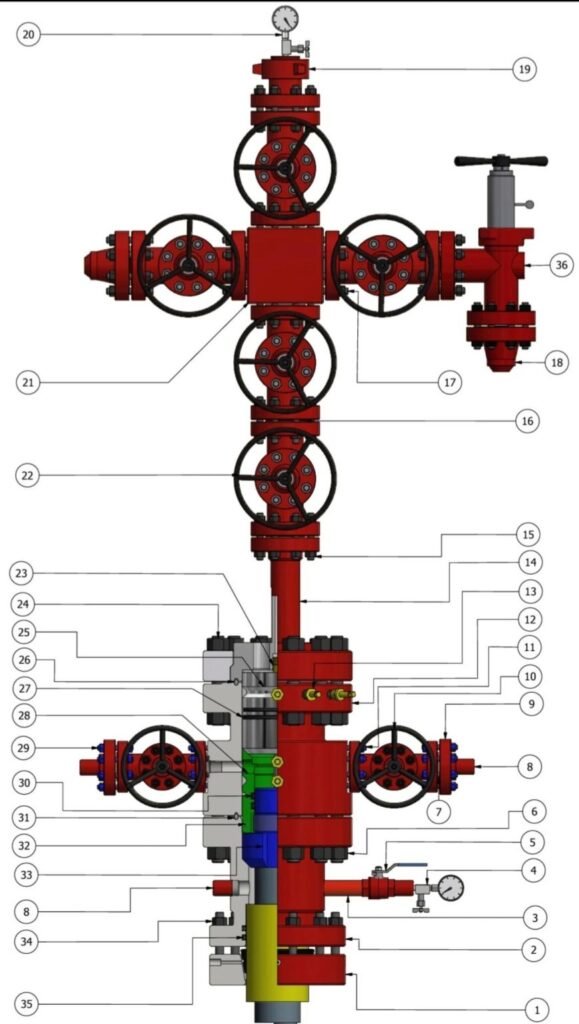

The wellhead and Christmas tree are essential components of an oil or gas that help control the flow of fluids and ensure safe and efficient operation. Here are the main components of ahead and Christmas tree;

Wellhead:

1. Casing head: The casing head is the first component of the wellhead and serves as the interface between the surface casing and the wellhead equipment.

2. Tubing head: The tubing head provides support and a means of sealing the annular space between the production tubing and the production casing.

3.Casing spool: The casing spool is a piece of wellhead equipment that provides a means of attaching the casing head and tubing head to the surface casing.

4. Casing hanger: The casing hanger is a component that supports the weight of the casing during installation and operation.

5. Tree cap: The tree cap is used to close and seal the wellhead during maintenance and shut-in operations.

Christmas tree:

1. Tubing head spool: The tubing head spool is a component of the Christmas tree that provides a means of attaching the production tubing to the tree.

2. Master valve: The master valve is a large valve located at the top of the Christmas tree that controls the flow of fluids from the wellhead.

3. Wing valves: Wing valves are smaller valves located on the sides of the Christmas tree that provide additional control over the flow of fluids.

4. Choke valve: The choke valve is a specialized valve used to control the flow rate of fluids from the wellhead.

5. Pressure gauges: Pressure gauges are installed on the Christmas tree to monitor the pressure levels in the well.

These components work together to control the flow of fluids, monitor pressure levels, and ensure the safety and efficiency of the wellhead and Christmas tree operations.