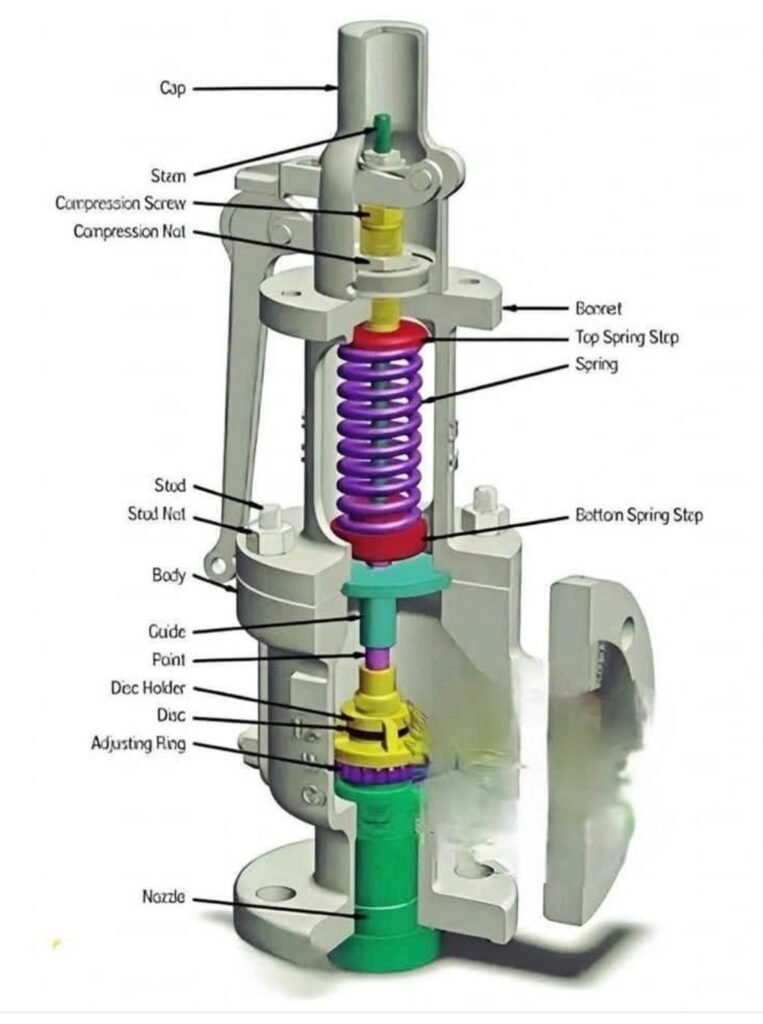

The image shows a pressure relief valve, also known as a safety valve, which is designed to protect systems from overpressure.

Here’s some information about it:

It automatically releases excess pressure to prevent damage or failure.

It opens at a predetermined pressure set point.

After releasing excess pressure, it closes again to prevent further flow.

It is commonly used in boilers, pressure tanks, and compressed air systems.

The valve is spring-loaded, with the spring force opposing the pressure.

When the pressure exceeds the spring force, the valve opens.

Oversizing safety valves can lead to issues such as leaks and premature failure.

It is designed for use with compressible fluids like gases, vapors, and steam.

Adjusted

“Adjusted” is a general term meaning that something has been regulated, adapted, or set to a specific measurement, condition, or operating point. In engineering and process control, this implies:

Regulation: The action of tuning equipment or a system to operate within desired parameters, such as adjusting engine valve clearance.

Set point: In automatic control systems, it is the desired reference value for a process variable (e.g., temperature, pressure, flow rate). The system attempts to keep the measured variable “adjusted” to this value.

Precision: In metrology and manufacturing, “adjusted” parts are those that fit with the degree of clearance or precision necessary for the correct operation of machines and equipment.

In short, while “blowdown” is a specific process or technical characteristic of discharge/depressurization, the term “adjusted” describes the state or action of regulating a system or component to an ideal or specified value or condition