What is a Blowout?

A blowout occurs when formation pressure exceeds the pressure control measures of a well, causing an uncontrolled flow of hydrocarbons to the surface. This can lead to fire, explosions, and environmental disasters. The most infamous blowout in history is the Deepwater Horizon disaster in 2010, which resulted in significant oil spills and loss of life.

Types of Blowout Preventers (BOPs)

There are two main types of BOPs used in drilling operations:

1. Annular BOP

A flexible, donut-shaped rubber seal that closes around different pipe sizes or even an open hole.

Provides primary well control and is used for routine pressure control operations.

2. Ram BOP

Uses hydraulic rams (steel blocks) to close the wellbore.

Different types of rams include:

Pipe Rams: Seal around a specific pipe size.

Blind Rams: Completely shut off the well when no pipe is inside.

Shear Rams: Cut through the drill pipe and seal the well in emergency situations.

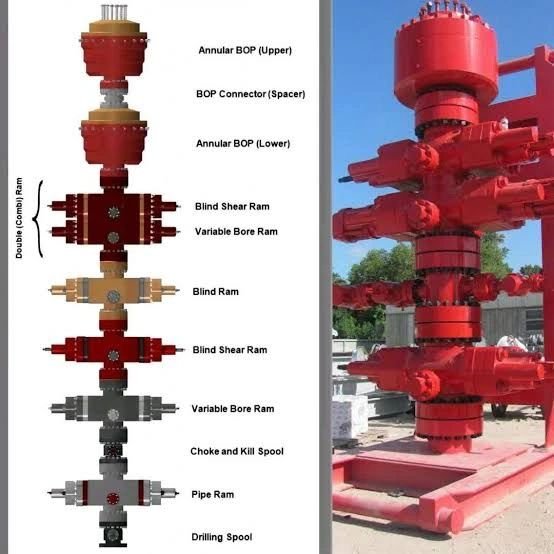

BOP Stack Configuration

A typical BOP stack consists of multiple BOP units arranged in a sequence to ensure redundancy. The arrangement usually includes:

Annular BOP at the top for flexibility in sealing.

Multiple Ram BOPs below to provide secure shutoff mechanisms.

Choke and Kill Lines to control well pressure by circulating drilling fluid.

How BOPs Work

1. Normal Operations: The BOP remains open, allowing the drill string to move freely.

2. Well Control Situations: If unexpected pressure surges occur, the BOP is activated to seal the well.

3. Emergency Scenarios: In case of total loss of control, shear rams cut the drill pipe and completely close the wellbore.

Maintenance and Testing

To ensure reliability, BOPs undergo:

Routine pressure tests as per industry regulations.

Regular inspections and maintenance to detect wear and tear.

Function tests before deployment to verify operational readiness.

Regulations and Safety Standards

Regulatory bodies like:

API (American Petroleum Institute)

BSEE (Bureau of Safety and Environmental Enforcement)

OSHA (Occupational Safety and Health Administration)

enforce strict guidelines on BOP design, maintenance, and operation to minimize blowout risks.