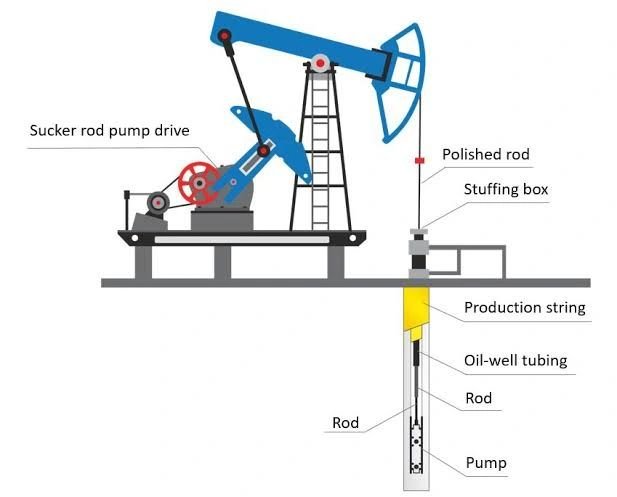

How Sucker Rod Pumps Work

Sucker rod pumps operate using a reciprocating motion powered by a surface pumping unit. The key components include:

1. Pumpjack (Surface Unit): Converts rotary motion into vertical reciprocating motion.

2. Sucker Rod String: A series of connected rods that transfer motion to the downhole pump.

3. Downhole Pump: Located at the bottom of the well, it consists of a barrel, plunger, valves, and seals to lift the fluid.

The pumping process works as follows:

Upstroke: The plunger moves upward, creating a vacuum that draws fluid into the pump through a standing valve.

Downstroke: The plunger moves downward, closing the standing valve and opening the traveling valve, allowing fluid to move upward.

Continuous Cycle: This cycle repeats, pushing fluid toward the surface.

Types of Sucker Rod Pumps

There are two primary types of sucker rod pumps:

1. Tubing Pumps

The barrel is part of the tubing, allowing larger fluid volumes to be lifted.

Used for high-production wells.

2. Insert Pumps

The pump barrel is installed inside the tubing, making maintenance easier without pulling the entire tubing string.

Suitable for wells with variable production rates.

Advantages of Sucker Rod Pumps

Cost-Effective: Lower capital and operating costs compared to other artificial lift methods.

Reliable and Durable: Suitable for long-term use with proper maintenance.

Efficient in Low-Volume Wells: Works well in mature fields with declining reservoir pressure.

Easy Maintenance: Can be repaired or replaced without removing the tubing (for insert pumps).

Limitations of Sucker Rod Pumps

Depth Limitations: Less effective in wells deeper than 10,000 feet due to rod string weight and mechanical wear.

Gas Interference: High gas content can reduce pump efficiency and cause operational issues.

Paraffin and Sand Issues: Can lead to pump failures if the well has excessive solid production.